Floating fish feed processing machine includes fish feed processing machine, fish extruded feed processing machine, fish pellet feed coating machine, fish fresh soft pellet feed processing machine, one-step pellet feed processing machine, first sinking and then floating pellets Complete feed processing machine, normal temperature, normal pressure floating pellet feed processing machine, etc.

It is reported that the current floating fish feed processing machine in the world mainly includes:

1. Floating fish feed pellet maturation machine

In order to make the pellet feed in the water does not immediately disperse, generally in the hard pellet fish feed machine with steam maturation device, so that the feed to increase the stickiness.

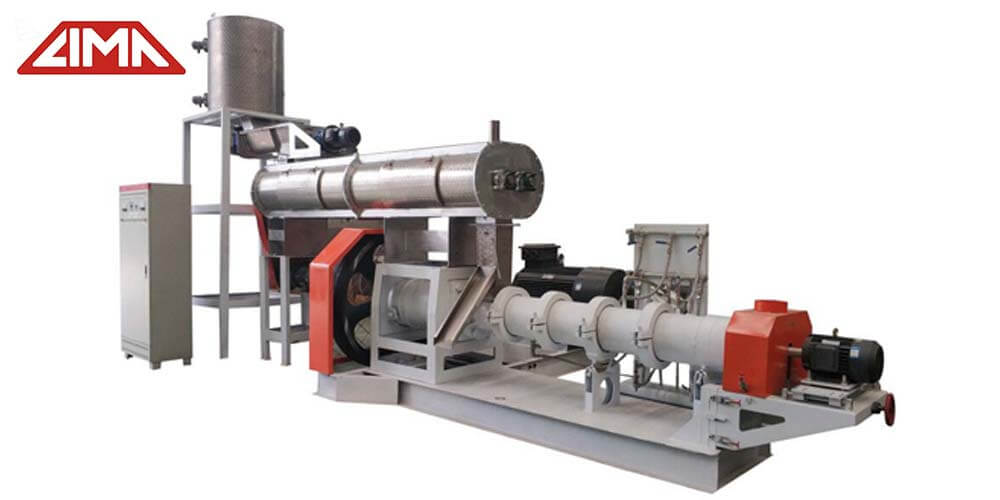

2. Floating ish feed puffed processing machine

In order to develop new feed sources, puffed pig hair, feathers, livestock manure to make it feed. In addition to cottonseed phenol and other toxins, puffing soybean meal, vegetable cake, cottonseed cake, etc.

3. Floating fish feed pellet coating machine

In order to extend the qualitative time of pellet feed in the water, generally at the outlet of the pellet fish feed machine with oil spray film machine, but because of the high moisture of the particles at that time, the finished product moisture content is greater than 16%, it is appropriate to dry first after spraying.

4. Fresh soft floating fish feed machine

The fresh feed is beaten into a paste by a beater, mixed with other powder feed, and processed into fresh soft pellet feed to keep the active material of live bait.

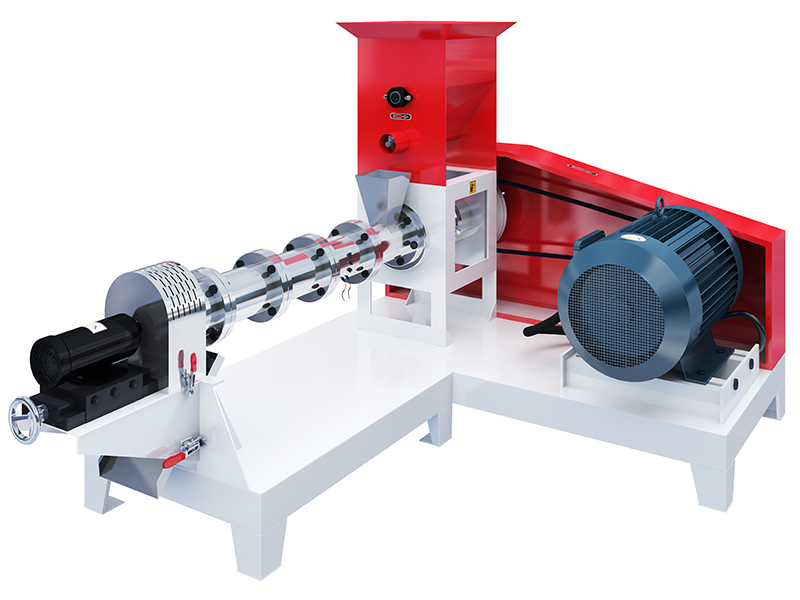

5. One-step floating fish feed processing machine

The machine does not need to add water steam and feed in the processing process, dry in and dry out. When the moisture content of raw materials is less than 12%, the moisture content of the product is less than 10.2%, no need to dry.

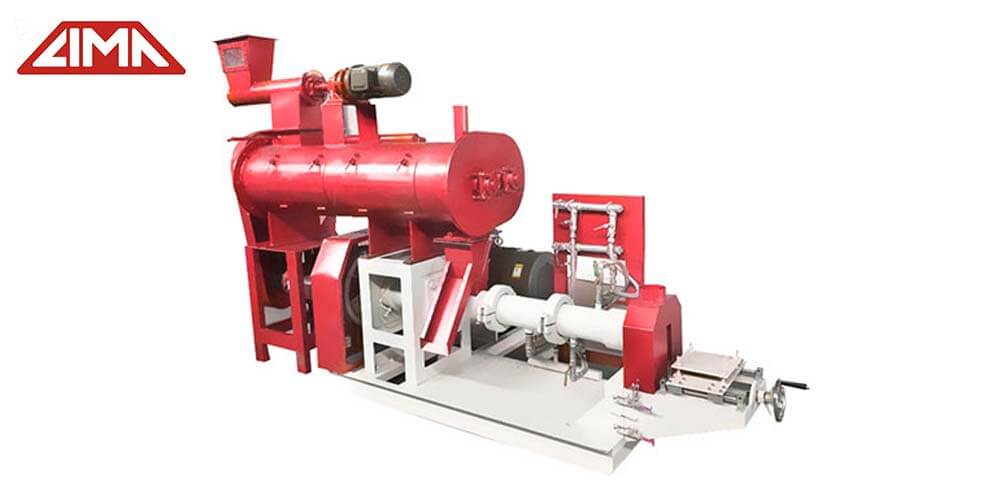

6.The First sink then float floating fish feed processing sets of machine

Its products are recommended by the United Nations shrimp pellet feed, it does not disintegrate after the water, a few hours after floating on the surface, which can reduce the pollution of water bodies and save the feed.

7. Room temperature, atmospheric pressure floating fish feed machine

The machine does not need heating facilities, at room temperature and atmospheric pressure processing of granular feed can also “immediately float”, and float for several hours without disintegration.

8. Ultra-micro crushing processing machine

In order to make the feed easy to digest and absorb, generally use no sieve ultra-micro crushing technology, used to feed larger fry, but also as raw materials for fish feed pellet.

9. Floating fish microencapsulated feed machine

It can make micro-particles outside the natural envelope, and then spray-dried into shape, feed particles 5 microns to 10 microns in diameter, up to 800,000 grains per milligram.

Floating Fish and shrimp feed machinery in the gradual separation from the livestock feed processing machinery, self-contained system. Aquaculture only fully realized mechanization, modernization, yield, and quality can be significantly improved.